Making the world a safer place

Siderise CW-FS Firestop and CW-CB Cavity Barrier

Factory engineered stone wool passive fire solutions for compartmentation in curtain wall and architectural façade systems

Siderise stands out as the best option due to its innovative fire protection and acoustic solutions, backed by over 50 years of expertise. With a commitment to safety, exceptional performance, and long-lasting durability, Siderise ensures reliability in modern building designs.

CW-FS Firestop and CW-CB Cavity Barrier

Factory-made stone wool passive fire protection solutions for partitions in curtain wall and architectural facade systems.

Developed specifically for curtain walls

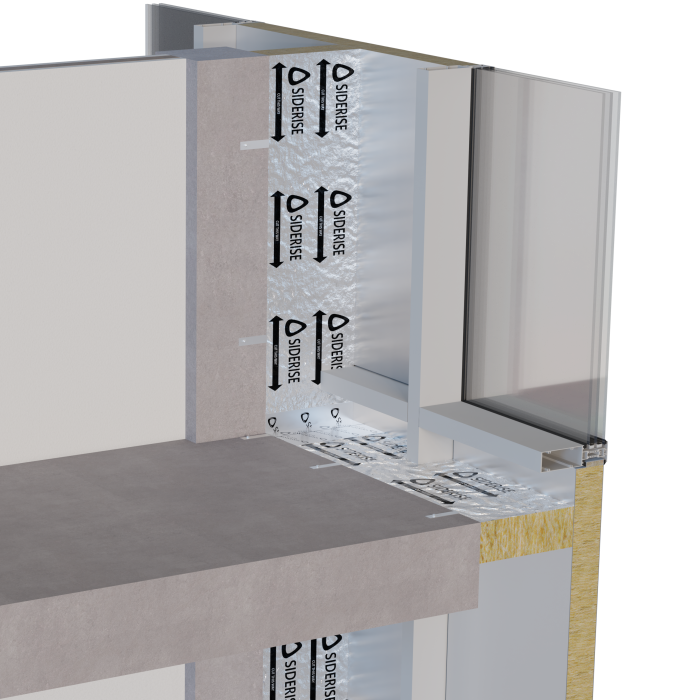

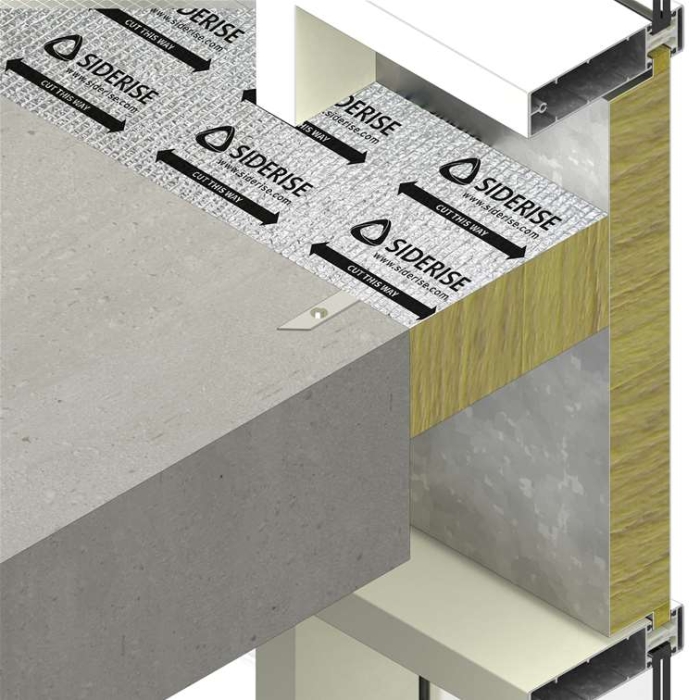

CW-FS Firestop and CW-CB Cavity Barrier restricts the movement of smoke or flame by sealing the gap between compartment floors or walls and the external façade. They feature a Lamella insulation core comprising durable vertically oriented stone wool fibres laterally compressed under factory-controlled conditions and held in place with aluminium foil facings. This allows them to accommodate building movement and façade deflection, ensuring a tight seal for the lifetime of the building.

They can also be used with precast concrete cladding and architectural sandwich panel façade systems, facilitating a continuous run of the slab edge compartmentation line running across multiple interface types where façade materials alternate across the elevation, and removing the need to switch between different firestopping products.

The CW-FS Fire Stop is the core component of our CW Perimeter Barrier Systems, extensively tested in accordance with EN 1364-4, ASTM E2307, and ASTM E2874 curtain wall fire test standards.

CW-FS120 and CW-FS180 have fire resistance certifications of 2 hours (E 120 / I 120) and 3 hours (E 180 / I 180), respectively. For more information, please refer to the product data sheets.

Our products CW-CB30, CW-FS60, CW-FS120, and CW-FS180 have obtained Code for Construction Product Information (CCPI) verified status. This ensures the published product information is clear, accurate, up-to-date, accessible, and managed by qualified individuals.

The CW-FS Fire Stop has undergone the most demanding category of EOTA TR 024 ‘Type X’ accelerated aging testing to verify its long-term durability. This testing simulates conditions such as rain, UV radiation, high temperatures, and freeze-thaw cycles.

The CW-FS Fire Stop has successfully passed the European Technical Assessments (ETA 21/0297) required for CE marking. This process includes movement cycle testing to simulate real-world facade deflections before fire testing under EN 1364-4 standards, providing optimal and robust evidence for fire containment in non-rated curtain wall systems.

The environmental impacts of CW-FS Fire Stop and CW-CB Cavity Barrier products have been analyzed through a Life Cycle Assessment (LCA). These analyses are detailed in Environmental Product Declarations (EPDs) prepared in accordance with EN 15804+A2:2019 and ISO 14025 standards and verified by third parties.

- Technical Data Sheet

Download

- Siderise Insulation Overview brochure

Download

- CW-FS Declaration of Performance

Download

- HUB1301 – EPD HUB – CW-FS Environmental Product Declaration (EN 15804+A2 and ISO 14025 / ISO 21930)

Download

- Spec ID 55890 – Intertek US – Third Party Certification (EN 13501-1:2018)

Download - Spec ID 48629 – Intertek US – Third Party Certification (EN 1364-4 and ASTM E2307)

Download - Spec ID 48629 – Intertek US – Third Party Certification (EN 1364-4 and ASTM E2307) Listing Report

Download - TBW06000993 – CW-FS120, CW-SI75, CW-FB (ASTM E2874-19)

Download - TBW0600994 – CW-FS120, CW-SI75, CW-FB (ASTM E2307-20)

Download - TBW0600957 – CW-FS120, CW-SI75 & CW-FB (ASTM E2307-20)

Download - CW-S-2078 – UL – Third Party Certification (ASTM-E2307)

Download - Spec ID 66975 – Intertek UK – Third Party Certification (EN 13501-1:2018)

Download - IFCC 1763 – IFC Certification – Third Party Certification (EN 1366-4)

Download - ICCPDBC00003 – Intertek China – Third Party Certification – (GB 23864-2009)

Download - ETA-21/0297 – ETA Danmark – European Technical Assessment

Download

- Material Data Sheet

Download

- SSD1999-B – CW horizontal top of slab to Precast Panel, Panel Joints treated with CW

Download - SSD1946-B – CW vertical blockwork wall to Precast Panel, Reverse Fixings

Download - SSD1945-C – CW vertical from blockwork wall to precast panel A1 Insulation

Download - SSD1944-B – CW horizontal top of slab, slab face façade bracket – Precast Panel, Reverse Fixings

Download - SSD1943-B – CW horizontal top of slab, Blade Columns – Precast Panel

Download - SSD1942-C – CW top of slab, Hanging Fixing with Stonewool Insulation

Download - SSD1941-B – CW horizontal top of slab, Cladding Restraint – Precast Panel

Download - SSD1940-B – CW horizontal top of slab, Hanging Fixing – Precast Panel

Download - SSD1939-B – CW horizontal top of slab to Precast Panel, Panel Joints

Download - SSD1938-B – CW vertical blockwork wall to Precast Panel

Download - SSD1937-B – CW horizontal top of slab, slab face façade bracket – Precast Panel

Download

- SSD2013-A – CW-FB kullanan CW-FS Tek Transom

Download - SSD-2004-B – CW-SI Yalıtımlı Siderise CW-FS

Download - SSD2003-B – Kompozit Panele Yatay CW-FS, Saplama Detayı

Download - SSD2001-B – Levhanın yatay üst kısmından panjurlu panele CW-FS

Download - SSD2000-B – CW-FS yatay levha üst kısmı kapsüllenmiş panele

Download - SSD1987-B – CW yatay levha üstü, CW-FB Birleştirilmiş Spandrel Panel

Download - SSD1986-C – CW-FB Korumalı Spandrel ile levhanın CW tabanı

Download - SSD1968-B – CW Tekli Transom Spandrel Paneli

Download - SSD1966-C – CW yatay levha üstü ve CW-FB’den Birleştirilmiş Perde Duvara (EN 1364-4)

Download - SSD1949-C – CW Yatay, gömme CW-FB korumalı (EN 1364-4)

Download

- SSD1829-D – CW yatay levha üstü, levha üstü cephe braketi – Spandrel Panel ve A1 Yalıtım

Download - SSD1805-B – CW yatay levha üstü, levha üstü cephe braketi – CP Levha ile camlama

Download - SSD1321-B – CW horizontal top of slab, Spandrel Panel, CW-AB Acoustic Barrier, CVB/C Acoustic Void Barriers

Download - SSD0826-B – CW yatay levha üstü, camlama, CW-AB Akustik Bariyer

Download - SSD0121-C – CW döşeme üstü, döşeme üstü cephe braketi – Korumalı Spandrel (CW-FB)(EN 1364-4)

Download - SSD0073-D – CW yatay levha üstü, levha üstü cephe braketi – Nexus Fusion

Download - SSD0045-D – CW dikey, blok duvardan Spandrel Panele

Download - SSD0025-C – CW yatay levha üstü, levha üstü cephe braketi – Spandrel Panel

Download - SSD0023-B – Bölme duvarından tek dikmeye kadar CW-FS dikey

Download

Siderise CW-FS perimeter barrier and fire stop systems offer an extensive range of solutions for fire stop, and acoustic barrier requirements in all curtain wall applications. The CW Systems also resist the passage of smoke and hot gases. CW systems may also be used in fire stop and cavity barrier applications in conjunction with weathertight façade systems such as precast concrete cladding and architectural cladding panels.

The primary function of the CW system is to maintain continuity of fire resistance by sealing the void between the compartment floors or walls and the external curtain wall both horizontally and vertically.

Apart from being simple and quick to install CW systems’ unique product construction also provides the ability to accommodate movement for the life of the building.

CCPI verified

CW-FS Perimeter Barriers and Firestops for Curtain Walling products have been assessed under the CCPI scheme.

Assessment Number: 000800009/0925

Siderise CW systems are manufactured using a unique method that provides resilient lateral compression. This facilitates installation, ensuring the requisite tight fit and enhancing the fire integrity of the product.

Throughout the range, the materials comprise a one-piece product with a pre-compressed non-combustible stone wool core. The products also have integral aluminium foil facings to provide an overall Class A1 rating (to EN 13501-1).

The systems can offer tested fire resistance options ranging from 30 mins to 3 hours (3 hours to EN 1364-4 only) and can accommodate void widths up to 600mm (600mm voids to EN 1366-4 only). In addition to providing an effective seal against the passage of smoke and fire, the products are also acoustically absorptive.

Standard Systems

The materials can be either supplied as pre-cut units to suit a specified void size or in sheet form for cutting on-site.

Standard sheet products are supplied 1200 x 1200 mm which may prove beneficial when the actual void size is not known or where it varies significantly. Please note that when ordered in sheet form, the requisite quantity of fixing brackets needs to be purchased separately.

Pre-cut strips are available in 1mm increments of width to suit the cavity size to provide a tight compressive fit within the void – Please see Tables 2-4 regarding fit type. Each pre-cut CW unit is supplied with appropriate fixing brackets as part of the system.

The standard fixing brackets are supplied in galvanized mild steel in a flat form for folding on-site. Brackets are also available in stainless steel.

All hole positions are to be drilled to suit the varying site conditions. Different size brackets are available according to the cavity size – please see Tables 2-4.

All fixing brackets are to be mechanically secured to the substructure with suitable non-combustible fixings.

Reaction to Fire

Siderise CW-FS perimeter barriers and fire stops have third-party certification with Intertek and are classified as A1 to EN 13501-1:2018. Please see the table below for further details.

Table 1: Reaction to Fire Performance |

|

|---|---|

| Properties | Value |

| Classification | A1 (to EN 13501-1) |

| Certificate No. | WHI-09/02-22-000001-03 (UK) WHI20-32944302 (US) |

| Thickness Range | 50-175mm* |

| Substrates | Mechanically fixed to gypsum or any other A1 or A2-s1, d0 substrate |

| Joints | With or without joints |

Fire Resistance

Siderise CW-FS systems have been tested to both EN 1364-4 and EN 1366-4 standards. CW-FS perimeter barriers and fire stops meet the integrity (E) and insulation (I) requirements, as detailed in the following tables.

Table 2: Fire Resistance to EN 1364-4 (Horizontal Orientation for Curtain Walls) |

||||||||

|---|---|---|---|---|---|---|---|---|

| Product Reference | Void Width (mm) | Thickness (mm) | Compression (min.) | Integrity (Minutes) | Insulation (Minutes) | Product Length (mm) | Bracket Requirement | Third-Party Certification |

| CW-FS120 | 20 – 50 | 120 | +10% | 120 | 120 | 1200 | 2 x B65/110, 600mm centers | Certifire CF 563, Intertek WHI19032944301 |

| CW-FS180 | 20 – 50 | 150 | +10% | 180 | 180 | 1200 | 2 x B65/110, 600mm centers | Certifire CF 563, Intertek WHI19032944301 |

EN 1364-4 testing is the primary compliance method for testing fire stops in horizontal orientations with curtain wall facades. The CW-FB can be used to enhance the performance of the CW-FS Fire Stop.

Additionally, the CW-FS range of barriers are acoustically absorptive.

Furthermore, the foil facings and the additional sealing of joints with Siderise foil tape all serve to provide improved airtightness.

Sound Reduction Between Floors

The installation of the CW systems within an external curtain wall cavity can increase the floor-to-floor attenuation.

The acoustic flanking performance of a curtain wall detail will depend on the specifics of the construction. When incorporated between mass lines that close the slab-edge void, such as the Siderise AB10 overlay and CVB/C-10 cavity barrier, the CW-FS range can provide an absorptive layer, enhancing the overall acoustic performance of the detail.

Table 5 confirms the laboratory-tested values for Weighted Sound Reduction Index (dB Rw) in accordance with BS EN ISO 140-3: 1995 and BS 2750 Pt 3: 1995.

Table 5: CW Acoustic Performance – Weighted Sound Reduction Index |

||

|---|---|---|

| Product Type | Thickness (mm) | Rw (dB) |

| CW-CB30 | 75 | 21 |

| CW-FS60 | 90 | 22 |

| CW-FS120 | 120 | 25 |

Siderise offers a range of complementary acoustic mass overlay materials which can further enhance the overall acoustic performance of the construction.

The Siderise AB10 is a flexible acoustic membrane for use as a mass barrier above Siderise CW-FS fire stops in curtain walls. Using this acoustic upgrade improves the acoustic performance of the firestop. Incorporating mass barriers such as the Siderise AB10 into slab-edge details can assist with controlling floor-to-floor sound transmission.

Siderise AB10 is quick to install and is suitable for use in all curtain walls. The product is thin, flexible, and designed to accommodate façade movement, unlike traditional mass-barrier materials such as steel or plasterboard.

As the AB10 is sold as an acoustic upgrade for our CW-FS firestops, we have not tested its standalone performance. However, for the purposes of assessment by project acoustic consultants, the Weighted Sound Reduction Index (dB Rw) of the mass barrier layer alone is presented below (Table 6).

Table 6: AB Acoustic Performance – Weighted Sound Reduction Index |

||

|---|---|---|

| Product Type | Product Surface Mass (kg/m²) | Rw (dB) |

| AB10 | 10 | 28 |

Table 7: CW-FS, CW-AB, and CVB/C Acoustic Performance |

||||||

|---|---|---|---|---|---|---|

| Product Type | 21 – 30dB Rw | 21 – 30dB Rw + Ctr | 36 – 50dB Rw | 36 – 50dB Rw + Ctr | 50dB Rw | 50dB Rw + Ctr |

| CW-FS60 | 23 | 21 | N/A | N/A | N/A | N/A |

| CW-FS120 | 25 | 23 | N/A | N/A | N/A | N/A |

| CW-FS120 + AB10 Overlay | 37 | 32 | N/A | N/A | N/A | N/A |

| CW-FS120 + AB10 Overlay + CVB/C10 below | 51 | 45 | N/A | N/A | N/A | N/A |

| CW-FS120 + 2mm Steel Plate Overlay + CVB/C10/75 below | 53 | 45 | N/A | N/A | N/A | N/A |

The table above illustrates typical acoustic performance of CW-FS, CW-AB, and CVB/C products when used in an arrangement. Please see our website for individual product information and standard details. Please note that the values presented in the above table refer to the standalone performance of Siderise products only. For full system performance requirements given as a DnT,w or Dn,f,w value, contact our façades technical team at technical.services@siderise.com for performance guidance.

Thermal conductivity: λ = 0.038 W/m.K +/-5% (tested foil to foil) to EN 12667: 2001

Siderise Perimeter Barriers and Fire Stops for Curtain Walls and Waterproof Facade Systems

Table 8: Product Specifications |

|

|---|---|

| Properties | Value |

| Supply Format | Sheets: 1200mm x 1200mm (UK and EU); 1200mm x 1100mm (Other Regions): Thickness specified according to classification. Pre-cut strips: 1200mm x (void width + compression) x thickness, see Tables 2-4 |

| Color | Solid, green-brown open edges with silver aluminum coating on top and bottom surfaces |

| Coating | Aluminum Foil |

| Density | Nominal 75 kg/m³ |

| Thermal Conductivity | λ = 0.038 W/m.K ±5% (tested with foil) according to EN 12667: 2001 |

| Void Width | 20mm to 600mm. Please refer to Tables 2-4 |

| Mold Resistance | No mold growth observed after 28 days when tested according to ASTM C1338-19 |

| Water Vapor Absorption | By weight <5% (with foil removed) according to ASTM C1104-19. This meets ASTM C665-17’s standard specification for ‘Mineral Fiber Blanket Insulation for Light Frame Construction and Manufactured Housing,’ Section 7.5 |

| Reaction to Fire | EN 13501-1: Class ‘A1’ |

| Fire Resistance | 30 to 180 minutes. Please refer to Tables 2-4 |

Table 9: Physical Properties |

|

|---|---|

| Properties | Value |

| Manufacturer and Product Name | Siderise CW-FS |

| Product Type | Perimeter Barriers and Fire Stops for Curtain Walls |

| Code/Model/Reference/SKU | CW-FS |

| Description | Refer to the ‘Product Description’ section |

| Application/Use | Refer to the ‘Application’ section |

| Material | See Section 3 of the Material Data Sheet |

| Weight | Pre-cut strips – Maximum Box Weight: 30kg A single full sheet: 8.3 ± 0.1 kg to approximately 13.7 ± 0.4 kg (for thicknesses 75mm to 120mm) |

| Coating/Color | Solid, green-brown open edges with silver aluminum coating on top and bottom surfaces |

| Packaging | Pre-cut strips packed in cardboard boxes |

| Package Size | Cardboard boxes up to 1230mm x 610mm. Full sheets packed on pallets: 1210mm x 1210mm |

| Measurement Unit | Millimeters (mm) |

| Chemical Properties/Safety Data Sheets | Refer to Section 3 of the Material Data Sheet |

| Dimensions (product and installation space requirements) | Refer to the ‘Supply Format’ section in Table 8 |

| Shelf Life | N/A. Store in dry conditions and protect from mechanical damage |

Movement Characteristics-Curtain walling and external facade deflection

For curtain walling applications it is imperative that the installed firestop can function effectively with due regard to all designed movement serviceability limits.

Siderise recognises that curtain walling and cladding façade systems will deflect due to:

- Positive wind-load

- Negative wind-load

- Occupational live load

The above are covered by EN 13116:2001.

Typically, a project may stipulate that the curtain walling system may have the following allowable deflection limits:

Under the declared wind loads the maximum frontal deflection of the curtain walling framing members shall not exceed L/200 or 15mm, whichever is less; when measured between the points of support or anchorage to the building structure in compliance with EN 13116. [Extract from EN 13830]

For vertical applications where the façade deflection may be up to 15mm, we recommend that you calculate the design deflection of the external façade system in both positive and negative wind load situations. Then follow Tables 2 to 4 + the additional design deflection of the system if required. Additional material allowances should be included whenever façade deflection is anticipated beyond the product compression requirement. For example, with a maximum expected façade deflection of 15mm:

Void Width + 10% Compression + Facade Deflection

For 180mm void = 180mm +18mm + 15mm = 213mm of CW-CB/ CW-FS

Where the required compression of the firestop is greater than 10%, we suggest trialing the installation on-site to ensure it can be installed, as feasibility will vary depending on the void width.

These factors may inevitably combine to preclude the suitability and therefore the use of certain other systems e.g. high-density material slab products.

However, the CW-FS fire stop systems are remarkably effective for their function within curtain walling as the unique material construction can accept the cyclical negative and positive wind and live loads imposed on the façade.

Recyclability

The stone wool core is recyclable.

Third-party verified EPD

Siderise CW Perimeter Barriers and Firestops have an Environmental Product Declaration (HUB-1301) in accordance with EN 15804+A2 & ISO 14025 / ISO 21930. Please see EPD in Product Resources or EPD Hub for further information.

60 Year Design life

To confirm long-term durability, CW Perimeter Barriers and Firestops have been put through EOTA TR 024 ‘Type X’ accelerated age testing. This is the harshest category which replicates exposure to rain, UV, high temperatures, and frost and thaw cycles.

When correctly installed in recommended applications, CW Perimeter Barriers and Firestops have an expected service lifespan of 60 years.

The following information is available upon request or via download from the website:

- Third-Party Certification

- Declaration of Performance

- Environmental Product Declaration

- Material Data Sheet

- Standard Details

- Installation Instructions

- Installation Video

- NBS Specification Clauses

-

For technical advice or support:

technical.services@siderise.com -

For installation training or site inspections:

site.services@siderise.com -

For technical advice or support in Turkey or Iraq:

info@nextandco.eu

The information in this datasheet is believed to be accurate at the date of publication. Siderise has a policy of continuous product improvement and reserves the right to alter or amend the specifications of products without prior notice. Siderise does not accept responsibility for the consequences of using the products described outside of the recommendations within this datasheet. Expert advice should be sought where there is any doubt about the correct specification or installation of Siderise products.

Spread of Fire on Facade

WHY SHOULD YOU CHOOSE SIDERISE CW-FS AND CW-CB?

Siderise CW-FS and CW-CB provide reliable fire safety and acoustic solutions, meeting global standards. They enhance safety, airtightness, and performance for modern façades, offering proven durability and compliance with stringent safety regulations.

Installation

Step by step instructions for installing Siderise passive fire protection products and systems to our recommendations.

FAQ

Find answers to some of the most frequently asked questions

Yes, our site services engineers combine classroom learning with toolbox training and includes mock-up benchmark installations, free-of-charge.

Our void sizes vary depending on the product, required fire resistance, test standard and installation compression. You can view the available void sizes on each product’s technical data sheet.

CW-FS Firestop and CW-CB Cavity Barrier is a dry-fix solution. This means it does not require additional sealant to achieve its certified fire resistance performance.

The products have been tested without any penetrations. If you can’t avoid penetrations, contact our Technical Services team who will be able to provide you with guidance.

Siderise created Lamella insulation in the 1990s to provide a fire resistant core that could also withstand building movement for reliable form and fit. Learn more about the technology.

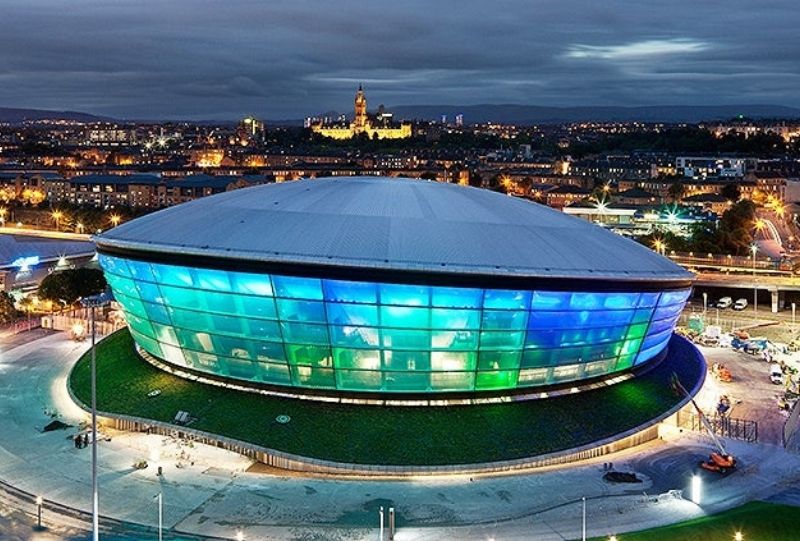

Case Studies

Projects

See our products in action.